Graphics Printing Technologies (GPT) announced is the sole UK distributor for the LamiDesk range of industrial flatbed lamination applicator machines. Options include uniquely an electrically driven roller to transit the bed (with footswitch control), LED bed illumination, and clear over-cutting mat

Sometimes, writing for a print magazine can have its humbling moments.

Coming to write an extended study of flatbed laminating systems, I

thought, naïvely, ‘how complicated can this be?’ Viewing the machines in

action, the benefits of having a flatbed over an upright laminating

system for large-format print applications seemed pretty clear: the

bridge controlled roller for single-man operation, the easier and more

accurate application meaning faster, better laminating—the facts are

persuasive. Yet the question all print providers have to ask is whether

the machine is really worth the investment. Laminating may not be the

largest part of what they offer, and with flatbed printers becoming more

popular, would this other large piece of equipment actually be useful

or simply gather dust?

My scepticism seemed initially well-placed, as across the board

manufacturers and suppliers were coy when it came to talking about this

technology. William Smith and Spandex, suppliers of the kingpin of the

applicator manufacturers, Rollsroller, both declined to comment on the

sales of the machines. After a number of failed attempts to get through

to Radecal, supplier of the Monster Applicator Table—though this could

have more to do with post-Christmas disorganisation—I did get the

feeling that the large-format print world was not terribly excited about

flatbed laminating systems.

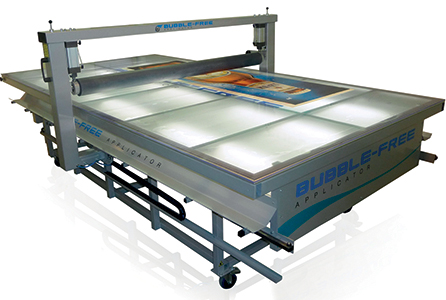

However, my whole perception changed on speaking to the dynamic Loic

Delor, managing director of Josero, a company especially well-known for

its large-format printer and inkjet expertise, but which also supplies

the Bubble-Free Flatbed Applicator, which comes in 1.5m (4' 11") to 2.2m

(7' 2") widths, and 2.2m (7' 2") to 7m (22' 11") lengths. Delor starts

out with a statement that proves I, and the industry at large, have the

completely wrong idea when it comes to the potential for this equipment.

The Bubble-Free Applicator from Josero, says managing director Loic

Delor, has multiple different advantages for a print provider, saving

time, manpower, and money

Delor begins by identifying that the first problem with an industry-wide

misunderstanding is purely verbal. He says: “Flatbed laminators don’t

really exist: they are called flatbed applicators. The difference is,

although you can laminate with a flatbed applicator—the same way you can

mount with an upright laminator—laminating is not its primary

function.” The confusion, is clear, as, even on Josero’s website, the

Bubble-Free is both described as a laminator—which it can do—and an

applicator—which it is, but Delor is very clear that the two machines

have different functions: “People do need to understand the difference

between an applicator and a laminator. Some people will tell me: ‘Well, I

can do everything on a laminator’ at which point we invite them over to

try the applicator. Then they try it and you see them thinking: ‘Oh

god’ and they realise the difference.”

These differences, according to Delor, are ones that can make—and have

made—huge improvements to a company’s workflow. From talking to

customers, Delor has pinpointed what the biggest advantages of the

equipment are. He says: “People use the flatbed applicator for various

reasons, the main one being the time saved. It is a lot faster to do

most things on flatbed than a laminator. If you use a laminator you have

to feed a whole sheet or board through the rolls and, say your board is

two metres long, you need a table in front and behind to stop the board

from falling. Obviously nobody has four metre long arms, so you need to

have two people, one at the back and one at the front. Again that makes

the process difficult and time consuming.”

O Factoid: The

very first flatbed applicator, the RollsRoller, was invented in 1996

when Reklamidé AB took on too much work and its head man Göran Johansson

realised they would never make their deadline. His solution was to

fabricate a table with a traverse beam and a roller would make it much

easier to apply material to the underlying surface, significantly

reducing production time. O

Delor also points out that it is a lot easier to make mistakes on an

upright laminator, especially when under the pressure of a large order:

“As the laminator is fixed and the roller is spinning, the board is

going through the laminator. That is much harder to handle than having

the roller moving above the board. The problem is that if the board is

not perfectly aligned and perpendicular to your roll when you start

sending it through, your board is going to be on an angle, so what

you’re trying to stick on it is going to be applied at an angle. It’s

going to crease and then you’ve ruined your print, you’ve ruined your

board, and you have to redo the order.” Delor is quite clear, however,

that for low productivity laminating or application, the flatbed may not

be necessary: “If you only need the odd board doing, and you’re quite

skilled, then a laminator is fine—everyone would say to do it through a

laminator before moving to a flatbed. But, if you get an order for, say,

20 boards you’re going to start having a massive headache.”

Delor goes on to say that a big difference between the two machines is

that the roller is made of much softer rubber on the applicator. He

warns: “You can still use it to laminate, but if you are just doing

laminating all day long, you’ll end up damaging the roll.”

Applied engineering

In terms of productivity, Delor says you can really start to see the

difference between an upright laminator and a flatbed applicator: “To

give you an idea, someone in a normal print shop who is skilled with a

laminator will do maybe three or four 8 x 4 boards an hour. With a

flatbed, you can do 25 an hour. And the other difference is, with a

flatbed you’re not going to have any problems: 25 boards will be 25 good

boards.”

So, the applicator is not simply a fancy step-up from an upright

laminator, says Delor. It has extra functions, on top of laminating,

which makes it a superior and more flexible piece of equipment, as Delor

highlights: “You can pretty much apply onto whatever you want; Foamex,

Dibond, any rigid material at all. You can also apply on clear film, two

films together, and of course you can laminate as well. You can mount

whatever you want. It is also really good for application tape. If

people want to sick a board somewhere then they can use the machine to

apply application tape and it will go on right the first time.

“Even big print firms who have flatbed printers that can print on almost

every substrate will still use a flatbed applicator. The point is that

flatbed printers can print on almost everything but not on everything.

You might have a substrate you can’t really print on, or that the

quality might not be good enough, or you might want to add a laminate

after you’ve printed it.

“For example, if you print on glass and then you want to laminate it,

you cannot put that through the laminator. You need a flatbed for that.

Also, sometimes to print on glass is very awkward so you might print it

on a normal solvent printer on a roll-to-roll clear adhesive and then

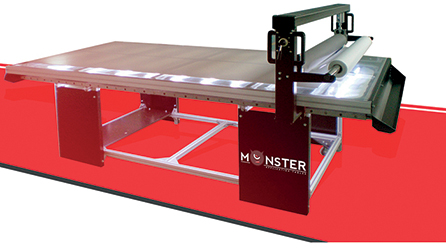

mount it on the glass.” The Monster Application Table (MAT), from

Radecal, for example, claims to be able to juggle multiple applications,

with various material types. The machine, which comes in sizes 1.4m x

2.5m to 1.6m x 4m, with an illuminated glass table top for more accurate

application and self-healing cutting mat, is especially suited to

flexible banners and applied signage. It is clear that, for printers who

already produce vinyl or adhesive print, the addition of a flatbed

applicator could help them offer more services to existing customers and

expand easily into other markets.

The Monster Applicator Table from Radecal comes with a twelve-month warrantee

GPT is another industry supplier that has seen the virtue of these

systems, and is the sole UK distributor of the LamiDesk range. It was

initially designed to help commercial printers moving into wide-format

cope with the extra workload and remove bottlenecks and the need for

high skill levels to carry out the vinyl application. Coming in lengths

of 1.6m, 3.5m, and 4.5m options, users can choose to either run

lamination automatically with its motor drive and foot control to make

it a true single person operation, or manually using button operation.

The machine has also got around the need to use an over table gantry to

improve ergonomics.

“We are extremely impressed with the superior construction, quality,

reliability, and cost point of this new commercial flatbed laminator.

With the improved productivity offered by the inbuilt motor feature of

LamiDesk, our customers will be able to easily handle growing volumes of

lamination and short turnaround times while meeting business growth

goals,” says Shaun Thompson, general manager at GPT.

He continues: “This is a market that has traditionally been dominated by

one or two major players. However, we believe the LamiDesk offers some

unique benefits, build quality and value for money.”

Dispelling myths

One setback of the flatbed applicator is that it doesn’t necessarily

come cheap—it is a serious investment like any other finishing

equipment. Top of the range is Rollsroller, and they come with the price

tag. Its entry level model, the Rollsroller Light, launched by Spandex

in 2013, which comes in 3.4 x 1.45m and 2.8 x 1.4m, starts at £7,900.

The range goes up to the enormous Premium range—the largest of which

comes in at a whopping 1.7 x 10.8m starting at £10k, with additional

accessories available, such as an extra roller to create to work

stations, an extension table, side trays, and bed end media holders.

You can buy a laminator for £1000, or £13,000. They are both

laminators, but there are going to be differences—you get what you pay

for”

It may be tempting to search the market, especially internationally, for

a cheaper option. However, when it comes to purchasing, Delor is

adamant that there is no point in buying a cheaper machine, because

cutting corners will end up wasting you money in the long run. Or, as he

says: “Rollsroller invented this technology 25 years ago, they

innovated the product, added all the different accessories, and they are

the most expensive. You can buy a laminator for £1,000, or £13,000.

They are both laminators, but there are going to be differences—you get

what you pay for.” Delor then points out a number of factors to take

into account: “On flatbed applicators the key point is that it needs to

be a welded frame. You can’t have it bolted. A lot of people tried out

cheaper tables which were bolted, the benefit of that being so you can

move it around. But at the end of the day those tables weigh 500kg and

the bridge is very heavy. So, if you leave the table out, it’s going to

start to wobble, then it won’t be flat, and you can’t apply properly.

That’s why you need a welded table.

(Above & below) Rollsroller’s range of flatbed applicators, supplied

by William Smith and Spandex, span from the Light—a smaller, lighter,

entry level model—to the Premium, which comes in sizes up to 5’ 7” x 35’

5”

“The next thing is the warranty: Other than Rollsroller, we are the only

ones offering a five year warranty on our Bubble Free Applicator. All

the others are one or two years. This is important because it’s a

product you are going to keep for ten or 15 years so you need to make

sure you’ve got something that is sturdy.” Delor continues: “Then you

have the lights. The advantage of the glass with light top is that if

you print backlit you can see what the print will look like immediately,

like a print proof box. But also it is a lot easier to align your vinyl

with the board when you’re mounting because you can see through it. “A

lot of products have neon lights. Rollsroller has LED lights and so do

we. Obviously there are environ-mental benefits but furthermore, with

LED, you get uniform light on the bed. LEDs also don’t use much power so

if the lights are on all day, it doesn’t matter.”

A term bandied around as another advantage is when the flatbed comes

with a bridgeless roller, such as Rollover’s Application Table, as it

makes it easier to move flexible material from one end to the other.

Delor advises against this: “When you don’t have a bridge, you operate

the roller from one side only. The force is applied only on one side so

in the long run the roller will go askew.

Rollsrollers also come with optional accessories, such as side trays,

self-healing cutting mats, or an additional roller to create a second

workspace

“It’s a lot cheaper to make a table without a bridge. However,

Rollsroller have been making tables for 25 years. It’s no huge secret—if

they didn’t need a bridge, they wouldn’t build them with bridges.”

Heated debate

A final pitfall, says Delor, is the worst of all, and that is when a

table offers heated rollers. Though he says very few manufacturers

actually do this, it is something that printers ask him about. He is

adamant on this point: “The advantage of heated rollers? Absolutely

nothing. It’s actually something you shouldn’t do. It’s the opposite of a

benefit: it’s a pain in the arse.

“The reason heated rollers ended up being used on applicators is because

it was taken from the laminator. When heated, glue will dry and clear

more quickly, so you will not get what’s called the ‘silver effect’.

This comes about when a layer of glue is not completely dry. If you try

and apply the laminate when the glue is cold, you will see a layer of

what looks like tiny air bubbles developing. It’s not air, it’s glue,

and it takes about 24 hours to disappear. If you laminate with heat,

that goes straight away and you get no silvering.

Rollover’s Flatbed Applicator features a bridgeless roller, which makes

it easier to move material from one side of the bed to the other, though

has the risk of going askew

“On an applicator, however, when you heat up the vinyl, it will stretch.

If the vinyl has stretched and you put your board on, by the time you

get to the other side of the board then the vinyl is bigger than the

board. It is pretty silly.”

We have installed more than 25 and every single customer has sent me

an email two days later telling me they can’t believe they hadn’t bought

one before”

Delor is positive about the future of the application table, mostly due

to the positive reaction he gets from his customers after installation:

“We started selling the applicator two years ago. We have installed more

than 25 and every single customer has sent me an email two days later

telling me they can’t believe they hadn’t bought one before. It just

saves them so much time.” In regards to the investment, Delor notes that

the technology is at its peak, so a single investment is just that:

“There is no need to upgrade, so once you get one you never need to

change it.”

It seems as if the flatbed applicator—as I am now inclined to call it—is

one of those hidden gems of the industry that has advantages but,

because of some misunderstanding of its function and abilities, has not

been so much in the limelight. In essence the machines are quite simple

conceptually; a flatbed that can apply any adhesive onto any

substrate—but since its conception a lot of research and development has

gone into making it the ultimate wide-format-friendly tool for printers

operating at a very high productivity rate and to a very high standard.

Your text here...

Your text here...